一级标题

一级标题

Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat:

Warning: Undefined variable $public in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

Warning: Trying to access array offset on value of type null in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

,. Or call

Warning: Undefined variable $public in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

Warning: Trying to access array offset on value of type null in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

directly.

Mixing a fertilizer seems simple—until your sprayer lines clog, your injector stops, or a “milkshake” forms in the tank. That mess wastes time, money, and nutrient value. Worse, it can stress plants and cut yield. Let’s fix it with clear “don’t mix” rules and practical steps.

Most fertilizer problems come from compatibility failures: calcium reacting with phosphate or sulfate, or poor water quality (hard water, high pH) triggering precipitation. You can prevent this with a jar test, correct mixing order, and a simple compatibility chart mindset—especially with liquid fertilizers and fertigation.

Mixing a fertilizer

As a China-based manufacturer and exporter, I’ve helped distributors, farms, and OEM brands troubleshoot fertilizer compatibility issues on real projects. The goal of this guide is simple: help you keep every nutrient soluble, protect equipment, and improve fertilizer efficiency—without guesswork.

Why does fertilizer compatibility matter in real tanks and lines?

Which fertilizer should not be mixed?

Why calcium nitrate with phosphate is a classic failure?

Can you mix calcium with sulfate or magnesium?

How do water quality and water pH trigger precipitation and clogging?

What is a jar test and how do you run it correctly?

What mixing order prevents compatibility problems in a tank mix?

Dry blending vs liquid: physical compatibility, salt, and critical relative humidity.

Foliar and crop protection tank mix tips.

When you mix fertilizers, you’re not just combining “plant food.” You’re combining salts, acids, bases, and ions that can react. If the reaction creates something insoluble, it will precipitate out of solution, settle to the bottom, and eventually clog filters, nozzles, or emitters. This is one of the biggest compatibility problems in fertigation and spray work. (Ask IFAS – Powered by EDIS)

Compatibility also affects what plants can absorb. If a nutrient drops out as a solid, nutrient availability falls—even if you paid for that fertilizer. Think of it like money stuck in a closed drawer: it exists, but you can’t use it.

From the manufacturer side, we see the same pattern worldwide: farms push for fewer passes (time-saving), distributors want fewer SKUs (simplify inventory), and brand owners want “all-in-one.” That’s why compatibility issues show up again and again—especially in concentrated stock tanks and injector systems.

Here’s the clear, practical “don’t mix” list used by many agronomy teams and fertigation guides:

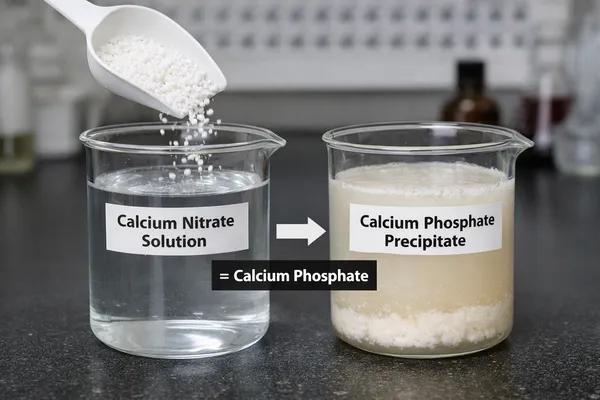

Calcium nitrate + phosphate fertilizers (e.g., MAP/DAP, monoammonium phosphate, ammonium phosphate) → forms calcium phosphate (insoluble) and causes precipitation.

Calcium (or calcium ammonium sources) + sulfate fertilizers (including ammonium sulfate, magnesium sulfate) → can form calcium sulfate (gypsum-like solids), leading to clog risk.

Phosphates and sulfates mixed with calcium or magnesium in the same tank → widely recommended to avoid due to precipitation in tank/pipeline.

Highly alkaline materials + certain ammonium products may drive pH up and increase scaling/solids; in some cases it can reduces nitrogen value via ammonia loss (especially with alkaline mixes).

Nitrate sources like potassium nitrate often behave well in many irrigation waters (but don’t assume—run a jar test).

Many potassium products are generally soluble, but watch chloride sensitivity (e.g., potassium chloride) for certain crops.

Key takeaway: the “red flag” ions are calcium, phosphate, and sulfate. When they meet at high concentration, combinations can lead to solids.

If you remember one rule, remember this: calcium nitrate with phosphate is a troublemaker in the same tank.

What happens? Calcium from calcium nitrate reacts with phosphate (from MAP/DAP or other phosphate sources) to form calcium phosphate, which is insoluble. It precipitates out, then builds sludge, then blocks lines.

That’s why many fertigation maintenance resources say the safest policy is to avoid mixing—and if you must mix, avoid these pairs or separate them into different injection points or different time windows.

Practical rule of thumb:

If your plan includes calcium nitrate and any phosphorus fertilizer, don’t put them in the same stock tank. Apply them separately, or use a split schedule so the nutrient stays available.

calcium nitrate with phosphate

The second big problem is calcium + sulfate. Even if your mix looks okay at first, it can form fine crystals that later settle to the bottom or plate out inside irrigation lines.

A common greenhouse mistake is mixing magnesium sulfate (Epsom salt) with calcium nitrate. That’s a direct route to precipitation and injector trouble.

So what if you need both magnesium and calcium? Many programs choose nitrate and magnesium sulfate alternatives carefully (for example, using magnesium nitrate in certain formulations) to reduce sulfate conflicts. The exact choice depends on crop program, local water, and budget—but the compatibility logic stays the same.

Quick guidance:

Need calcium? Keep it away from sulfate and phosphate in the same tank.

Need sulfur? Apply sulfate products in a separate injection event from calcium sources.

Even if the fertilizer pair is “okay,” your water quality can turn it into a mess.

Two common triggers:

Hard water / high bicarbonate water can cause calcium and magnesium to precipitate—especially when you inject certain fertilizers, including calcium nitrate or related calcium products.

Water pH that is too high can encourage scaling and solids. Adding aqueous ammonia (or other high pH materials) can push pH up and cause salts to form crystals that clog emitters.

What I recommend in real projects (simple and effective):

Test your source water. Know hardness, bicarbonate, iron/manganese, and water ph.

Keep most fertigation solutions acidic or neutral when possible (many operations use acid injection strategies; always follow label and safety).

If needed, add ph adjusters (again—label and safety first) to reduce scaling risk and keep nutrients soluble.

A jar test is a small-scale compatibility test before you risk a full tank. It’s one of the best low-cost tools for safe mixing.

Many Extension resources recommend jar testing to detect settling, separation, sludge, heat, odor, or precipitation before application.

Start with water (use the same water source you will spray or fertigate with).

Add products one by one, following the label mixing order if provided.

Shake or stir after each addition (simulate agitation).

Wait 15–30 minutes.

Look for:

flakes, crystals, or haze (signs it may cause precipitation)

gel, sludge, layers, or floating scum

sediment that starts to settle to the bottom

If it fails: avoid mixing those two products. Use separate applications or different forms.

Tip from field experience: If you plan to mix more than two products, jar test the full combination, not just pairs. Three-way interactions can surprise you.

jar bar

Even compatible products can fail if you dump them in randomly. Correct proper mixing helps keep salts dissolved and reduces localized high concentration reactions.

A widely used rule in mixing guides is: follow the label. If the label is unclear, add from the most diluted to the most concentrated, with agitation between steps.

| Step | What to add | Why it helps |

|---|---|---|

| 1 | Water (½ tank) | Dilution reduces reaction risk (start with water) |

| 2 | Acidifier / pH control (if used) | Helps keep solution stable and less alkaline |

| 3 | Fully soluble fertilizers (non-calcium first) | Lower risk before calcium |

| 4 | Calcium products (only if compatible) | Add late to avoid local hotspots (mixed with calcium only when safe) |

| 5 | Micronutrients (micronutrient) | Some forms react with phosphate; test first |

| 6 | Top up water + continuous agitation | Keeps products in the tank uniform |

Important: This doesn’t “make incompatible compatible.” If your combination includes calcium nitrate with phosphate or calcium with sulfate, mixing order will not save it.

Not all compatibility is chemistry. Some is physical.

With dry granule blends, moisture matters. If humidity is high (think “sticky air”), some fertilizers absorb water, cake, and lose flow. That’s where critical relative humidity becomes relevant: above a certain humidity, some products pull moisture fast and clump. This is a storage and blending headache for distributors and bulk buyers.

Keep storage dry and sealed.

Avoid blending materials that cake easily during humid seasons.

Use proper conditioning, coating, and packaging.

In tank mix work, high salt content can reduce solubility of other products and increase compatibility risk—especially when using liquid carriers or concentrated stock solutions. (This is one reason using liquid carriers needs extra caution.)

Foliar programs and crop protection mixes can be efficient, but they increase risk. The more you put in, the more you invite trouble.

Do run a jar test for every new combo.

Do keep dilution high and agitation steady.

Don’t assume “it worked last year” if your water source changed.

Don’t mix nutritionals randomly with pesticides without checking label guidance and compatibility factors like pH and formulation.

If a foliar program needs nitrogen plus micronutrients, consider simpler mixes and separate passes when risk is high. A failed tank costs more than an extra pass.

If you’re responsible for product selection, sales, or system performance, use this quick checklist:

Confirm the fertilizer products you plan to combine are chemically compatible (especially calcium + phosphate/sulfate).

Test your hard water risk: bicarbonates, Ca/Mg, iron, and water ph.

Run a jar test before every new program or supplier change.

Keep a written mixing order SOP for your team.

If you see haze, flakes, crystals, or sludge—stop and redesign the mix.

Which fertilizer should not be mixed in the same tank?

Avoid mixing calcium nitrate with phosphate fertilizers (MAP/DAP) and avoid calcium with sulfate sources. These combos commonly create insoluble solids that precipitate out of solution and can clog lines.

Can I mix calcium nitrate with monoammonium phosphate?

In most cases, no. Monoammonium phosphate provides phosphate that can react with calcium from calcium nitrate to form calcium phosphate solids.

What is the fastest way to check fertilizer compatibility?

Do a jar test using the same water source and product rates. Watch for settling, sludge, layers, heat, odor, or precipitation before you scale up.

Does water pH really matter for fertilizer mixing?

Yes. High pH and bicarbonates can increase scaling and precipitation risk in fertigation systems, especially with calcium and magnesium chemistry.

Are nitrates always safe to mix?

Not always, but many nitrate fertilizers (like potassium nitrate) tend to have fewer precipitation problems in many irrigation waters. Still, compatibility matters, so always test.

If my tank mix looks clear, am I safe?

Not guaranteed. Some reactions form fine crystals slowly or only after temperature changes. That’s why I recommend a jar test, good agitation, and keeping incompatible pairs out of the same stock tank.

Don’t mix calcium nitrate with any phosphate fertilizer (MAP/DAP): it can form calcium phosphate and cause precipitation.

Avoid calcium with sulfate (including ammonium sulfate and magnesium sulfate) in the same tank—high clog risk.

Water quality (hard water, bicarbonates) and water pH can trigger solids even when products seem fine.

Use a jar test and follow label mixing order every time you change products, rates, or suppliers.

Keep systems clean, agitate well, and separate incompatible nutrients into different tanks or different application windows.

If you want, tell me what fertilizers you’re currently using (e.g., urea, ammonium nitrate, urea ammonium nitrate, MAP/DAP, potassium sources, micronutrients) and your water report (hardness + pH). I’ll map a safe tank plan that protects equipment and keeps every nutrient working.