一级标题

一级标题

Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat:

Warning: Undefined variable $public in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

Warning: Trying to access array offset on value of type null in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

,. Or call

Warning: Undefined variable $public in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

Warning: Trying to access array offset on value of type null in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

directly.

Poor yields, uneven color, and weak plant health often come from one simple problem: the wrong fertilizer in the wrong place at the wrong time. It wastes money and frustrates growers. The fix is not “more fertilizer.” It’s choosing the right fertilizer for your crop, soil, and schedule.

Water soluble feeding is often “better” when you need fast, precise nutrient delivery—especially through irrigation systems or when you must fix a problem quickly. Dry granules can be better for long feeding and simple storage. Liquid fertilizer sits in the middle: flexible and fast, but it needs good mixing and careful handling. The best choice depends on crop stage, soil, climate, and the application method you can manage.

As a China-based manufacturer and exporter, we work with distributors, commercial farms, public projects, and OEM brands. The same question comes up again and again: “Which fertilizer form will give stable results with fewer headaches?” Let’s answer that with practical, field-tested logic.

When I say water-soluble fertilizers, I mean a dry fertilizer that dissolves into water and becomes a feeding solution. In trade terms, a soluble fertilizer is simply a dry product designed to mix cleanly and feed crops through water. You’ll often see powders or crystals designed to mix cleanly. This fertilizer type is popular when growers want quick control, steady feeding, and clean delivery through modern equipment.

Plants do not “eat” granules. They absorb water, and nutrients are absorbed in that water. When you feed in smaller, steady doses, nutrients are delivered closer to the active roots, so plants can absorb what they need with fewer swings. That supports plant growth and steadier plant health.

FAO describes fertigation as applying fertilizers through micro-irrigation directly to the region where most of the plants roots develop, which improves placement and control. In our export support work, this is why high-value farms often move from “one big feeding” to “many small feedings”: it supports uniform growth and development and reduces complaints about uneven color.

Quick reality check: faster delivery also means mistakes show up faster. If you overload concentration or ignore soil moisture, you can stress roots in a single day.

What are water-soluble fertilizers

Let’s use the phrase key differences once and keep it practical. In real projects, the differences that matter most are speed, placement, risk, and labor. No single type of fertilizer fits every farm, but this is the core of the liquid vs granular decision for most buyers.

| Factor | Solution feeding (dissolved in water) | Dry granules |

| Speed of response | Fast, visible changes when used correctly | Slower; depends on moisture and breakdown |

| Placement | Can target the feeding zone with drip irrigation | Often spread or banded; less precise |

| Risk | Over-application can spike salts fast | Granules can create “hot spots” |

| Operational fit | Great for controlled feeding and automation | Great for simple, low-tech operations |

Michigan State University notes that granular fertilizers can be “hot”, and roots may avoid a concentrated band—especially with high N and K.

From a buyer’s perspective, consistency is a big deal. Powders that dissolve well can stay uniform if they’re packed correctly, while dry blends can separate during handling. That’s why serious suppliers focus on anti-caking control, moisture barriers, and stable blending—because fertilizers ensure uniform performance across many dealers and climates.

Relative speed of visible response

Solution feeding: ██████████

Liquid fertilizer: ████████

Dry granules: ████

If you manage hundreds of hectares, “simple” often means fewer moving parts. Granules and liquid fertilizer can both deliver the same total N-P-K, but the workload looks different.

Granules usually win on storage, shipping, and spreading. That’s why they remain common in broad-acre programs and for distributors serving mixed growers. Liquids win on flexibility: you can adjust the program quickly when weather shifts or when you see nutrient deficiencies.

A common myth is that “liquid is always stronger.” In reality, granular and liquid fertilizers can provide the same total nutrient amount; the difference comes from placement, uniformity, and timing. MSU Extension highlights mobility differences, noting that nutrients in liquid form can be more mobile in the soil water solution.

For long programs, some growers prefer slow-release fertilizers or coated granules to reduce labor and keep nutrition steadier. That can be a smart baseline in rain-fed regions, while solution feeding handles the “fine tuning.” In other words, fertilizers come in different forms because farms come in different realities.

My buyer advice: choose the easiest system your customers will actually use correctly. A “perfect” plan that farmers don’t follow becomes expensive waste.

Fertigation is where solution feeding becomes very strong, because you deliver water and nutrients together in small doses. The International Fertilizer Association explains that fertigation helps deliver water and nutrients efficiently “exactly where they are needed.”

When nutrients are delivered close to demand, you often improve uptake and reduce losses from runoff or deep leaching. Peer-reviewed research in greenhouse vegetable systems reports that drip fertigation can increase water and N use efficiency and reduce N leaching compared with less controlled methods.

A 2025 study in greenhouse eggplant found that drip fertigation reduced N leaching by more than 70% and reduced N₂O emissions by more than 60% compared with conventional fertilization in that setting.

This is a big story for government and NGO programs because they often need measurable improvements, not marketing claims. In our experience, the farms that succeed with fertigation do three things well: filtration, calibration, and steady scheduling. When any one of these fails, results become uneven.

Illustrative “loss risk” chart (conceptual)

Broadcast granules on wet soil: █████████

Band granules near roots: ██████

Drip fertigation: ███

Most buyers shop by npk first, and that’s fine. But it helps to know how each major nutrient moves, because that changes which form feels “better.”

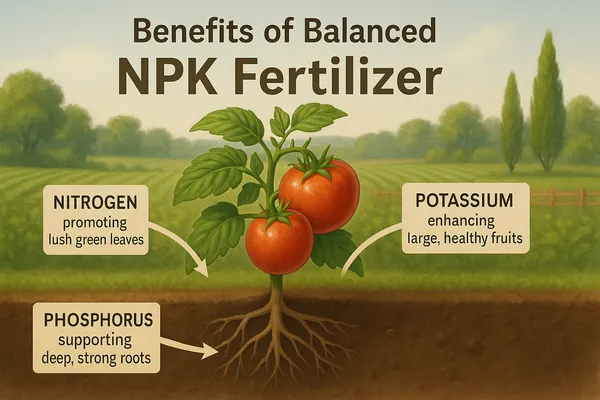

FAO notes nitrogen is the element most commonly applied in fertigation, and applications of phosphorous and potassium are also possible. This matches what we see with commercial farms: balanced essential nutrients drive stable yield, plant health, and root development.

A practical lens I use with buyers is this: if nutrients sit too far from roots, plants can’t access them; if you overload the zone, you can cause stress. So the “best” fertilizer is the one that keeps the root zone supplied safely and consistently.

NPK basics

Leaf sprays are not a replacement for a full soil program, but they can be a smart rescue tool. When you see clear nutrient deficiencies mid-season, foliar application can correct shortages faster than waiting for soil movement—especially for a micronutrient gap such as zinc.

A Missouri Extension guide explains that leaf feeding of chelated trace elements can correct an acute shortage faster than soil amendments in some deficiency situations.

Here’s the key: use leaf sprays for quick fixes and quality goals, not as your main feeding backbone. Done wrong, you can scorch leaves. Done right, you can save a season and protect quality.

Most fertilizer waste happens when timing is off. You apply too early, and rain moves it away. You apply too late, and the crop can’t recover.

Here’s a simple timing map I use when training distributor teams:

With fertigation, you can adjust programs weekly without re-spreading a full field. That supports specific plant needs and helps crops stay stable through heat or cloudy weeks. In controlled systems, small injections every two weeks can keep programs steady, especially for greenhouse crops and container production in a pot.

If you’re advising growers, tell them to watch the rooting area, not just the leaf. When soil dries, absorption slows. When soil is waterlogged, roots suffocate. A smart plan respects growth stages and the environment, and it keeps the root zone from swinging between “too hot” and “too empty.”

As a manufacturer and exporter, this is where we help buyers most. The best product is not only agronomy—it’s also logistics and brand risk.

Here’s a real pattern we see with distributors: a “two-SKU starter line” often sells better than a complex catalog. One importer built a basic line with a field-friendly dry base plus a high-analysis top-up for high-value crops. The result was fewer customer questions, cleaner inventory, and faster repeat orders. Once the market trusted the brand, we expanded into crop-specific formulas and private label packaging.

Simple decision table for distributors

| Buyer priority | Often favors |

| Lowest logistics cost per nutrient | Dry products (or high-analysis powders) |

| Fast in-season correction | Liquid fertilizer or solution feeding |

| Easy private label for many SKUs | Powders + custom blending |

| Large mechanized farms | Dry base + targeted supplements |

Here is what we ask OEM clients before we produce a private label:

Choosing a product spec

When you’re applying fertilizer through irrigation, think about emitter safety first. The FAO fertigation chapter stresses injectors installed before filtration in micro-irrigation, which helps protect the system.

If you’re selecting products for a dealer network, build clear instructions into labels and training. Farmers want confidence. They want a plan they can repeat. That’s where a strong supplier adds value: consistent quality, documented analysis, and fast technical answers.

| Scenario | Best fit | Why it fits |

| High-value vegetables under drip | High-analysis powders | Controlled feeding and fast response |

| Broad-acre grains with spreaders | Dry base program | Easy logistics and stable baseline |

| Orchards with variable soil zones | Hybrid program | Supports site-specific plant needs |

| In-season deficiency correction | Liquid / leaf spray | Fast response and flexible dosing |

One pro tip from export work: many failures come from “one-size analysis.” We prefer to design two or three formulas to match seasons and soil zones, so your product line stays simple for dealers but still feels tailored.

No. Solution feeding is “better” when you need precision and fast response. Dry base programs often win for simplicity and long feeding. Many farms use both.

Over-concentration. A strong solution can burn roots quickly. Start low, test EC, and scale carefully.

Often yes, but confirm compatibility and filtration. Some products clog emitters or react with hard water. A jar test and proper injectors help.

No. Leaf sprays can support quick corrections, but they cannot supply the full macronutrient load needed for yields.

It depends on concentration and freight. Dry products often ship nutrients more efficiently. High-analysis powders can also ship well.

Ask for COA, dissolution tests, recommended ranges for your crops, packaging options, and OEM/private label support.

Want help picking the right product line for your market?

As a China-based fertilizer manufacturer and exporter, we support private label formulas, stable supply, COA documentation, and packaging optimized for international shipping. Send us your crop list and target regions, and we’ll propose a practical portfolio that sells.