一级标题

一级标题

Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat:

Warning: Undefined variable $public in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

Warning: Trying to access array offset on value of type null in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

,. Or call

Warning: Undefined variable $public in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

Warning: Trying to access array offset on value of type null in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

directly.

Struggling with inconsistent crop yields or equipment malfunctions? The problem might be in your fertilizer tank mix. Mixing incompatible fertilizers can lead to nutrient lockout, crop damage, and costly equipment failure, sabotaging your efforts before they even reach the field.

The key to avoiding these issues lies in understanding fertilizer compatibility. Certain combinations, particularly those involving calcium, phosphate, and sulfate, should never be mixed in concentrated solutions. These pairings can react chemically to form insoluble solids, or precipitates, which clog sprayers and render essential nutrients unavailable to your crops. This guide will detail which fertilizers should not be mixed and how to ensure every application is both safe and effective.

In modern agriculture, efficiency is paramount. For commercial farm owners, agricultural distributors, and project managers, the ability to mix different fertilizers and crop protection products into a single spray solution saves time, labor, and fuel. However, this convenience comes with a significant risk: incompatibility. When you mix different fertilizers, you are combining complex chemical salts. If these salts react negatively, the consequences can be severe.

The most immediate problem is the formation of precipitates. These solid particles can quickly clog nozzles, filters, and irrigation lines, leading to uneven application and costly downtime for cleaning and repairs.[1][2] But the problems go deeper than just equipment. Chemical reactions can also “lock up” essential nutrients, making them unavailable for plant uptake even though they’ve been applied to the field.[1][3] For instance, mixing a calcium source with a phosphate source can create insoluble calcium phosphate, meaning your crops get neither the calcium nor the phosphorus you intended.[3][4][5] This leads to wasted resources and, more importantly, nutrient deficiencies that stunt growth and reduce yields.

As a leading fertilizer manufacturer and exporter, we’ve seen firsthand how a lack of understanding about product compatibility can undermine a grower’s success. Ensuring the chemical compatibility of the products in your tank mix is not just a best practice; it is a fundamental step in effective nutrient management and achieving the high yields your operation depends on.

Why is Fertilizer Compatibility So Crucial for Crop Health?

Fertilizer incompatibility isn’t a single issue but rather a spectrum of potential problems. These are generally grouped into two main categories: physical incompatibility and chemical incompatibility. Understanding the difference is key to diagnosing and preventing mixing errors.

Physical Incompatibility occurs when fertilizers don’t mix uniformly in the spray tank. This can manifest in several ways:

These issues are often related to factors like water temperature, inadequate agitation, or exceeding the solubility limits of a particular salt.[6] While physical incompatibility can still clog equipment, it doesn’t necessarily alter the chemical nature of the nutrients.

Chemical Incompatibility is more severe because it involves an irreversible chemical reaction between the active ingredients of the mixed products.[3] This is the type of incompatibility that occurs when you mix calcium and phosphate. The reaction forms a new, insoluble compound that wasn’t in the original products.[5][7] Other signs of chemical incompatibilities include a sudden shift in the solution’s pH, the release of gas (like ammonia from mixing ammonium fertilizers with alkaline solutions), or the generation of heat.[1][8] These reactions not only reduce nutrient availability but can also create compounds that are harmful to your crops or damage your spray equipment.[1][4]

Knowing which specific fertilizer combinations to avoid is the most critical piece of the puzzle. While you should always read the product label for specific instructions, some chemical pairings are universally problematic in concentrated solutions. As your partner in high-quality agricultural inputs, we want to ensure you have this essential knowledge.

Here are the primary combinations of fertilizers that should not be mixed in a concentrated form, like a spray tank or stock solution for fertigation:

| Product A | Product B | Why They Are Incompatible |

| Calcium-Based Fertilizers (e.g., Calcium Nitrate) | Sulfate-Based Fertilizers (e.g., Ammonium Sulfate, Potassium Sulfate, Magnesium Sulfate) | Forms Calcium Sulfate (gypsum), a precipitate that is not very soluble and will clog equipment.[1][5] |

| Calcium-Based Fertilizers (e.g., Calcium Nitrate) | Phosphate-Based Fertilizers (e.g., MAP, DAP, Phosphoric Acid) | Forms Calcium Phosphate, a highly insoluble solid that makes both calcium and phosphorus unavailable.[3][4][5] |

| Magnesium-Based Fertilizers (e.g., Magnesium Sulfate) | Phosphate-Based Fertilizers (e.g., DAP, MAP) | Can form Magnesium Phosphate, which precipitates out of the solution, especially in alkaline conditions.[5][7] |

| Ammonium-Based Fertilizers (e.g., Ammonium Sulfate) | Highly Alkaline Products (e.g., Potassium Carbonate, Lime) | Causes ammonium (NH₄⁺) to convert to ammonia gas (NH₃), which is lost to the atmosphere and reduces nitrogen efficiency.[1] |

| Unchelated Micronutrients (e.g., Iron, Zinc, Manganese) | Phosphate-Based Fertilizers | Can form insoluble metal phosphates, making the micronutrients unavailable for plant uptake. |

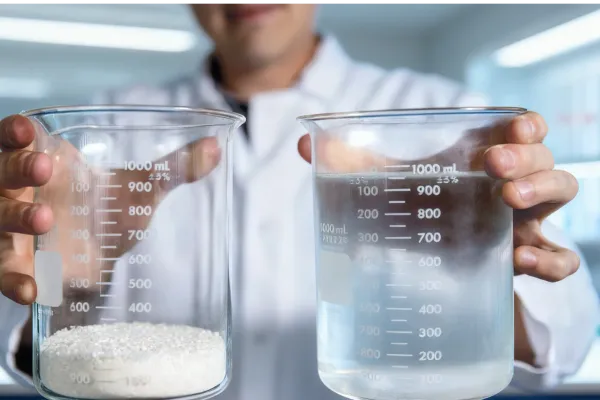

It’s clear that calcium is the main element to be cautious with. This is why in many professional fertigation systems, a two-tank system is used: Tank A typically holds the calcium nitrate, while Tank B contains the sulfates and phosphates to prevent these harmful reactions.[9]

This question comes up so often that it deserves its own section. The short answer is no, you should not mix concentrated solutions of calcium-based fertilizers with phosphate or sulfate fertilizers. The chemical reactions are swift and problematic.

When you combine calcium nitrate with a sulfate source like potassium sulfate or magnesium sulfate, the calcium (Ca²⁺) ions and sulfate (SO₄²⁻) ions bond to form calcium sulfate (CaSO₄).[1] This compound, commonly known as gypsum, has very low solubility.[10] While gypsum is a valuable soil amendment on its own, its formation inside a tank or irrigation lines creates a solid precipitate that leads to severe clogging.[1][5] The reaction is so predictable that it’s a classic example of chemical incompatibility.

Similarly, when calcium nitrate is mixed with a phosphate fertilizer like monoammonium phosphate (MAP), the calcium ions react with the phosphate (PO₄³⁻) ions. This creates calcium phosphate, another highly insoluble compound that falls out of the solution as a milky or chalky solid.[3][9] This reaction effectively removes both essential nutrients—calcium and phosphorus—from the solution, making them unavailable to your crops.[1][3] For any large-scale farming operation, this represents a significant loss of investment and potential yield.

The pH of your water and the final fertilizer solution plays a pivotal role in determining product compatibility and nutrient availability. The pH scale measures acidity or alkalinity, and drastic shifts can trigger unwanted chemical reactions or hinder a plant’s ability to absorb nutrients. Many nutrients are only available to plants within a specific pH range, typically between 5.5 and 6.5 for hydroponic and foliar applications.[4]

Mixing certain fertilizers can dramatically alter the solution’s pH. For example, ammonium-based fertilizers can make the soil more acidic over time, while nitrate-based fertilizers have a less acidifying effect.[3] If a tank mix becomes too alkaline, you risk the volatilization of ammonia from any ammonium-based fertilizer in the blend.[1] Conversely, if the solution becomes too acidic, it can increase the solubility of certain micronutrients to toxic levels or damage sensitive plant tissues during a foliar spray.

Furthermore, water quality itself is a major factor. “Hard water” is high in dissolved minerals like calcium and magnesium.[4] If you use hard water to mix a phosphate or sulfate fertilizer, you might see precipitation before you even add a second product, as the nutrients react with the minerals already in the water.[4][5] Therefore, adjusting the pH of your water before mixing can sometimes prevent compatibility issues.

For large-scale agricultural operations, tank-mixing fertilizers with pesticides (like fungicides, insecticides, or herbicides) is a common practice to improve efficiency. However, this adds another layer of complexity. The chemical compatibility between a fertilizer and a pesticide is not always guaranteed, and an improper mix can reduce the efficacy of both products or cause crop injury.[2][11]

Always check the labels of both the fertilizer and the pesticide for any specific warnings or instructions about tank mixing.[12] Many labels will explicitly state known incompatibilities. If no information is available, a jar test is absolutely essential.

A widely accepted best practice for mixing order is the WALES acronym:

This sequence ensures that products are added in an order that promotes proper dispersion and minimizes the risk of physical or chemical incompatibility.[13][14] Always fill the spray tank with at least half the required water before adding any products, and maintain constant agitation throughout the mixing process.[13]

How to Properly Mix Fertilizers and Pesticides?

A jar test is a simple, small-scale trial run that allows you to check for compatibility issues before committing to a full tank mix.[15] It is an indispensable risk-management tool that can save you from costly mixing errors, equipment damage, and crop failure. We strongly advise our clients—from fertilizer brand owners developing new formulations to commercial farm cooperatives planning their application schedules—to make this a standard procedure.

Performing a jar test before mixing is straightforward. Here’s how you do it:

5.If you observe any of these signs, the products are incompatible and should not be mixed.[14]

Even with knowledge of chemical compatibility, simple mistakes during the mixing process can lead to problems. As your manufacturing partner, we are committed to helping you achieve the best results with our products. This includes helping you avoid the common pitfalls that can compromise the performance of a high-quality fertilizer.

Here are some of the most frequent mixing errors to avoid:

Water is the universal carrier in most spray operations, but its quality can vary significantly. Factors like pH, temperature, and mineral content can all influence fertilizer compatibility.

As mentioned earlier, hard water, which is high in dissolved calcium and magnesium carbonates, is a major concern.[4] These minerals can react with phosphate and sulfate fertilizers to form insoluble precipitates.[5] For distributors and importers supplying regions with known hard water issues, recommending water conditioners or using chelated fertilizer formulations can be a significant value-add for your customers.

Water temperature also plays a role. Cold water slows down the rate at which soluble fertilizers dissolve.[4][6] If you’re mixing in cold conditions, you may need to allow extra time and agitation to ensure everything is fully dissolved before adding the next product. Trying to mix too quickly in cold water can lead to physical incompatibility and the formation of crystals or sediment.

How Does Water Quality Affect Fertilizer Compatibility?

Navigating the complexities of fertilizer compatibility can be challenging. For agricultural distributors, fertilizer brand owners (OEM clients), and managers of large-scale agricultural projects, ensuring product performance and safety is non-negotiable. This is where partnering with an experienced manufacturer like us makes all the difference.

As a leading China-based exporter of high-quality fertilizers, we do more than just supply products. We provide solutions. Our team of agronomists and chemists understands the science behind nutrient interactions. We can work with you to:

By choosing us as your supplier, you gain a partner dedicated to your success. We empower you to deliver reliable and effective nutrient solutions to your market, building trust and driving growth.

What happens if you mix incompatible fertilizers?

Mixing incompatible fertilizers can lead to chemical reactions that form solid precipitates.[4] This can clog spray nozzles and irrigation equipment, make essential nutrients unavailable to plants, and in some cases, create compounds that are harmful to your crops.[1]

Can you mix liquid fertilizer with granular fertilizer?

Yes, you can dissolve a water-soluble granular fertilizer to create a liquid solution. The standard ratio is about 1 cup of granular fertilizer per 1 gallon of warm water, which should be left to soak for 24 hours and then strained.[17] However, you must ensure the granular fertilizer is fully soluble and not a slow-release type, and you must still follow all compatibility rules if mixing it with another fertilizer.

Is it safe to mix fertilizers with pesticides?

It can be, but you must verify compatibility. Always check the product labels for specific tank-mixing instructions and warnings.[11][12] If there is any doubt, performing a jar test is the safest way to prevent a reaction that could reduce the effectiveness of the pesticide or harm the crop.[12]

Why can’t you mix calcium nitrate and magnesium sulfate?

You should not mix concentrated calcium nitrate with magnesium sulfate because the calcium ions (Ca²⁺) will react with the sulfate ions (SO₄²⁻) to form calcium sulfate.[1] Calcium sulfate (gypsum) is not very soluble and will precipitate out of the solution, causing blockages in your equipment.[1][5]

How can I be sure my fertilizer mix is compatible?

The most reliable way is to conduct a jar test.[15] Mix small, proportional amounts of the products in a clear jar using the same water you’ll use in your tank. Let it sit and observe for any signs of incompatibility like solids forming, layering, or gelling.

Does mixing order really matter?

Absolutely. The correct mixing order, often remembered by the WALES acronym (Wettable powders, Agitate, Liquids, Emulsifiable concentrates, Surfactants), ensures that each product is properly dispersed in the water before the next one is added.[13][14] This helps prevent physical incompatibility issues and ensures a uniform spray solution.

Understanding fertilizer compatibility is fundamental to maximizing your agricultural productivity and protecting your investment. By avoiding these common mixing errors, you ensure that your crops receive the precise nutrition they need to thrive. Contact us today to learn how our premium fertilizer products and expert support can benefit your operations.