一级标题

一级标题

Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat:

Warning: Undefined variable $public in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

Warning: Trying to access array offset on value of type null in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

,. Or call

Warning: Undefined variable $public in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

Warning: Trying to access array offset on value of type null in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

directly.

If your fertilizer costs keep rising but your yields stay flat, the problem may not be your soil—it’s often your drip lines only carrying plain water, not nutrients. Without the right water soluble products and a simple fertigation plan, you’re wasting money, time, and potential yield.

Water soluble fertilizer for drip irrigation is a special, fully dissolving fertilizer that mixes into the irrigation water and flows through your drip irrigation system. It delivers nutrients and water together to the root zone, matching crop needs by growth stages. This method, called fertigation, can save 20–40% fertilizer and 30–50% water while boosting yields and reducing runoff and risk of leaching.

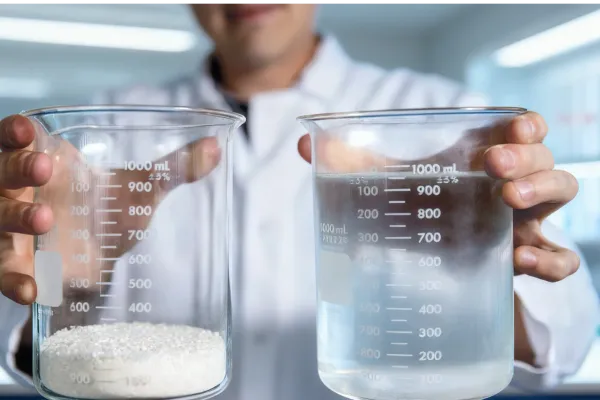

In simple words, water-soluble fertilizer (often written as water soluble fertilizer) is a fertilizer that dissolves completely in water and leaves almost no insoluble particles behind. That means it won’t clog emitters and can move smoothly through an irrigation system to feed every plant. Many products are NPK blends, like 20-20-20, or single nutrients such as urea or potassium nitrate.

When we design programs for our partners, we focus on solubility and clean raw materials with very low insoluble impurities. This is especially important because these fertilizers are used in fertigation systems and micro-irrigation where even small particles can block emitters. For high-value crops in the field, greenhouse, or even hydroponic setups, this type of water-soluble product helps provide precise nutrient delivery and gives the grower very tight control over nutrient supply.

Because they dissolve fully, these fertilizers come in various forms: straight nitrogen, phosphorus, or potassium, balanced multi-nutrient blends, and mixes with every key micronutrient the crop needs. Compared to granular products broadcast on the soil, water-soluble grades give faster absorption, higher nutrient availability, and are ideal when you want to optimize every kilo of fertilizer you apply.

drip irrigation system

Drip fertigation simply means sending fertilizer solutions through the drip irrigation network. The fertigation tank or dosing unit mixes fertilizer into the irrigation water, and the emitters drip nutrients directly into the soil around each plant. Scientists note that fertigation minimizes waste because fertilizers allow us to feed the root zone instead of the whole field surface.

By adjusting the program to growth stages—for example, more nitrogen early for vegetative plant growth, more phosphorus and potassium later for fruiting—you can enhance crop yield and crop quality while using less input. Studies show this approach can save 20–40% fertilizer and significantly improve crop performance thanks to better nutrient availability and more even nutrient concentration in the wetted soil.

From our experience as a Chinese fertilizer manufacturer working with large farms and grower cooperatives, the big advantage is precision. You can send nutrients exactly when the crop needs them. That means better crop growth, lower risk of leaching, less runoff into waterways and fewer problems with alga growth in canals and ponds.

Many types of fertilizers are technically “soluble,” but not all are safe for a drip irrigation system. In fertigation, we usually recommend:

For fertigation, we prefer clear, dust-free water-soluble powders or liquid fertilizer grades. Liquid fertilizers are popular in many markets because of their ease of use and fast mixing, but high-quality powders often give better shipping efficiency and longer shelf life. Either way, formulation quality matters. Good products dissolve quickly, have high solubility, and low insoluble impurities, which protects pipes and emitters.

We sometimes blend in organic fertilizer based components (like humic acids or organic chelates) when customers want more soil-health benefits. In that case, we pay close attention to physical properties, because systems require clean solutions that will not clog. Used correctly, these blends support strong plant growth in both open fields and protected landscape and greenhouse crops.

Traditional granular fertilizers are spread on the soil and rely on rain or overhead sprinkler systems to move nutrients downward. In many regions, this leads to uneven distribution, nutrients that leach below the root zone, and higher risk of leaching into groundwater. With fertigation, we can combine watering and fertilizing so that every plant gets the same dose at the same time.

This approach is also great for conserving water. Research from several countries shows that drip and fertigation together can reduce water use by 30–50% while maintaining or increasing yields. That’s because fertilizer and water move together as a front, staying close to the roots. This kind of nutrient delivery is one of the best ways to improve nutrient use efficiency and reduce waste.

When we support distributors and large farms, they often tell us that “drip plus water-soluble fertilizer gives faster response.” That is true. Because nutrients are already dissolved, absorption is quick, and you see greener leaves and stronger stems within days. Better crop performance and crop quality mean higher revenue, not just lower cost.

Water Soluble Fertilizer

Every crop has varying nutrient requirements over its life. Seedlings have soft roots and need gentle feeding; fruit trees during flowering and fruit set demand more potassium and phosphorus. Good fertigation lets you match the recipe to crop needs and growth stages, feeding exactly what the plant needs when it needs it.

As a manufacturer, we often design feeding charts that cover the full plant growth cycle. For example:

| Stage | Focus nutrients | Typical approach |

| Establishment | N + P + trace micronutrient | Light, frequent fertigation |

| Vegetative growth | More N, some K | Stronger doses, still frequent |

| Flowering / fruit | More P and potassium | Boosted K, controlled N to balance vigor |

| Finishing | Balanced NPK | Maintain crop quality, avoid excess salts |

Some programs also use foliar feeding as a support tool. A fine spray with a foliar mix can push nutrients directly into the roots or leaves, especially when temperatures are mild. Just remember: the main supply should still go through the fertigation system, because that is where you can optimize overall nutrient concentration and avoid leaf burn.

To run fertigation safely, you need simple but reliable hardware:

Many farms use a venturi injector that works with suction created by the flow of irrigation water. This setup pulls fertilizer solution from the tank into the line. You then adjust the injection rate to match the target parts per million in the line. Some more advanced systems use dosing pumps controlled by EC or flow sensors; these systems require a bit more investment but give very high precision.

When we ship products, we often help partners check compatibility with their fertigation system. For example, you shouldn’t mix certain calcium products with phosphorus or sulfate sources because they can form precipitates. That’s why we offer clear advice on chelate forms of micronutrient products, especially iron and manganese, which stay in solution better and protect emitters from clogging.

In all cases, backflow preventers and safety valves are essential when applying fertilizers through an irrigation system. They protect the main water source and ensure you always fertilize crops, not canals, wells, or neighboring land.

There are many brands on the market, so selecting the right product can feel confusing. Here are some key considerations we always discuss with our customers:

As a Chinese fertilizer factory, we produce tailor-made water-soluble and water soluble fertilizer blends for distributors, big farms, and OEM brands. Some partners prefer high-tech trace element packages; others want simple, robust formulas. In both cases, our goal is to provide precise nutrient delivery that fits their equipment, their budget, and their local regulations.

Finally, always look at your climate, soil, and landscape. Salty water, sandy soils, or heavy clay all change how fertilizer behaves. We routinely review soil and water tests to recommend programs that optimize yield while conserving water and protecting the environment.

selecting the right water soluble fertilizer formulation

Most of our partners use drip, but some also use micro-sprays or sprinkler systems. In all cases, a few simple rules make fertigation safer and more effective:

Remember that fertigation is watering and fertilizing at the same time. Research shows that when we feed through the system, fertigation minimizes nutrient losses, cutting runoff and deep leach losses and protecting groundwater. This is one reason regulators and development agencies now recommend drip irrigation with fertigation in many regions.

We also advise checking for slime, alga, or biofilm. These problems usually come from poor filtration, not from the fertilizer itself. Good maintenance and high-quality, low-salt products reduce risks and keep your system running smoothly for years.

One of our export partners manages a 200-hectare vegetable project supplied by drip irrigation. They switched from broadcast granular programs to a full fertigation program using our balanced 20-20-20 starter and high-K finisher. Within two seasons they reported:

A simplified comparison is shown below:

| Method | Fertilizer use (kg/ha) | Water use (mm/season) | Yield (t/ha) |

| Broadcast + flood | 100 | 600 | 50 |

| Drip + fertigation | 70 | 400 | 58 |

Field data like this matches published studies where farmers save 15–25% on fertilizer by using drip fertigation, while still increasing yields. For large distributors, government programs, and NGOs, this kind of result is ideal: higher production per drop, lower input per tonne.

As a manufacturer and exporter, we support such projects with custom blends, OEM labels for local brands, and on-site training so local teams can adjust nutrient concentration and scheduling themselves. This is how we help partners enhance crop productivity and build long-term, profitable business.

While this article focuses on drip and fertigation, sometimes growers ask about foliar feeding and small-scale use. The same water-soluble products can be sprayed as a foliar feed in orchards, fields, or even a garden. When used carefully, these sprays give quick correction of deficiencies, especially for iron, manganese, or other trace elements.

However, most nutrient uptake should still come from the soil through the roots. Whether you are managing a large commercial farm or a small landscape project, soil-based fertigation keeps nutrient availability more stable and reduces the chance of leaf burn. You can use both together: soil fertigation as the base, plus foliar sprays for emergencies.

As a leading manufacturer and exporter of high-quality fertilizer products based in China, we work every day with:

Here’s what we bring to your drip fertigation business:

Whether you need a standard fert line for vegetables or a premium brand for high-value crops, we help optimize your program, simplify daily work, and strengthen relationships with your farmers. For many partners, liquid fertilizers are popular; others prefer powders. In both cases, our products are used in fertigation systems across Asia, Africa, and beyond.

If you’d like, we can review your current fertilizer plan, your irrigation system, and your target crops, then design a step-by-step program to provide precise nutrient delivery and improve crop growth season after season.

Not all fertilizer products are safe for a drip irrigation system. You should avoid coarse granular and very insoluble materials because they may clog emitters. Choose clean water-soluble powders or liquid fertilizer specifically labeled as used in fertigation systems, and always filter the solution before injection.

Both. Small farms and even advanced garden users can benefit. A simple bucket and venturi injector already let you practice fertigation with accurate drip lines. Large farms add automation and smart controls, but the principle is the same: combine watering and fertilizing so fertigation minimizes waste and improves plant growth.

When designed well, it’s the opposite. Because you apply small doses more often, fertigation actually reduces runoff and deep leach losses. You keep nutrients in the root zone where the crop can use them, instead of flooding the soil with big one-time doses. This also reduces pollution risks to rivers and groundwater.

Yes, but be careful. Some combinations can form solids. For example, mixing certain phosphates with calcium in hard water can create insoluble impurities. That’s why many farms use chelate forms of iron and other micronutrient products. Always jar-test and follow your supplier’s guidance before applying fertilizers through the system.

Fertigation sends nutrients through the irrigation system to the soil and roots. Foliar feeding sprays nutrients onto the leaves. Foliar is good for fast correction of certain deficiencies, but roots take up most of the plant’s needs. In most projects, we use fertigation as the main tool and foliar as a support.

Start simple:

If you work with us, we’ll help you design the injection rate, crop recipes, and full program so your fertigation system is safe, efficient, and profitable from day one.