一级标题

一级标题

Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat:

Warning: Undefined variable $public in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

Warning: Trying to access array offset on value of type null in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

,. Or call

Warning: Undefined variable $public in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

Warning: Trying to access array offset on value of type null in /www/wwwroot/lvfertilizer.com/wp-content/themes/hyhadmin/header.php on line 350

directly.

Are your crops not growing as expected? Many farmers waste money on the wrong fertilizer type. Using mixtures when compounds are needed (or vice versa) leads to uneven nutrient distribution and poor yields. Your soil deserves better, and so do your profits.

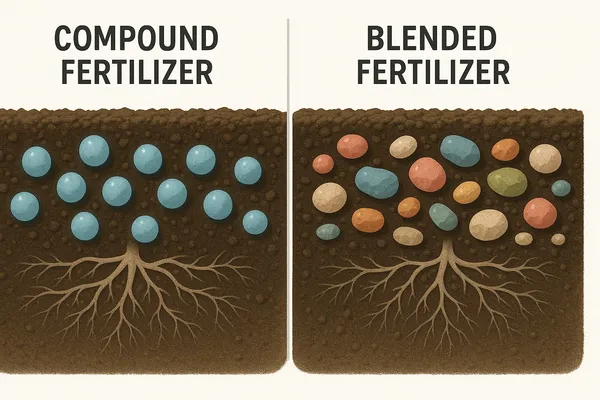

A compound fertilizer is made through chemical reactions that bind nutrients into uniform granules – every granule contains exactly the same nutrient ratio. A mixture (or blended) fertilizer is created by physically mixing separate fertilizer materials without chemical bonding, resulting in heterogeneous granules that retain their original properties. This fundamental difference affects how nutrients distribute in your soil and how plants access them.

Compound fertilizers stand out because of their production method. These fertilizers are created through chemical processes like granulation and ammoniation where raw materials react to form new compounds.

Every granule in a compound fertilizer contains the exact same ratio of nutrients. This means when you apply an NPK 15-15-15 compound fertilizer, each granule delivers equal amounts of nitrogen, phosphorus, and potassium to your soil.

NPK compound fertilizers ensures your crops receive balanced nutrition without “hot spots” or nutrient-deficient areas. The chemical bonding in compounds means nutrients dissolve together, providing coordinated release to plant roots.

Mixture fertilizers, often called blended fertilizers or BB fertilizers, are made by physically combining separate granular fertilizer materials without any chemical reaction between them.

In a mixture, each granule maintains its original nutrient content. For example, in a 10-10-10 blended fertilizer, some granules might be pure urea (nitrogen), others pure potash (potassium), and others phosphate.

Bulk blending fertilizers offer cost savings and customization options that many farmers appreciate, especially when specific nutrient ratios are needed for particular crops or soil conditions.

| Feature | Compound Fertilizer | Mixture/Blended Fertilizer |

|---|---|---|

| Production Process | Chemical reaction creating new compounds | Physical mixing of existing fertilizer materials |

| Granule Composition | Homogeneous – identical nutrients in each granule | Heterogeneous – each granule retains original composition |

| Nutrient Distribution | Uniform across field | Can segregate during transport or application |

| Nutrient Release | Coordinated release as granules dissolve | Independent dissolution based on component properties |

| Customization | Fixed ratios determined at factory | Highly customizable on-site |

| Cost | Higher per unit nutrient | More economical |

| Best For | Precision agriculture, high-value crops | Cost-sensitive farming, custom applications |

This comparison shows why understanding the difference matters for your farm’s productivity and profitability.

Compound fertilizers are your best choice when:

Case studies show compound fertilizers provide more consistent nutrient delivery, with less than 5% yield variation across different soil types compared to blended fertilizers that showed 15-28% variation.

Complex fertilizers with multiple nutrients are ideal for crops with specific nutritional needs at critical growth stages.

Mixture (blended) fertilizers work best when:

Blended fertilizers offer quick nutrient response with good solubility, delivering individual nutrients directly to plants as soon as they’re applied.

One of the biggest practical differences between compounds and mixtures is segregation risk.

Segregation happens when different components of a blended fertilizer separate during transport, handling, or application. This can create uneven nutrient distribution in your fields.

Studies note 20-30% nutrient deviation in blended fertilizers after transport/application versus less than 5% in compounds.

This image shows how segregation occurs:

The way nutrients become available to plants differs significantly between these fertilizer types:

Understanding this difference helps match your fertilizer choice to your crop’s growth cycle and nutrient needs.

When deciding between compound and mixture fertilizers, consider both cost and performance:

The right choice depends on your specific farming operation, crop value, and precision requirements.

To select the best fertilizer type for your needs:

Remember that soil testing should guide your nutrient application rates regardless of which fertilizer type you choose.

Compound fertilizers undergo sophisticated manufacturing processes:

This process creates chemically bound nutrients that work together in the soil.

Mixture fertilizers have a simpler production process:

This straightforward process allows for cost-effective production and customization.

Agricultural experts recommend:

Professional soil testing and agronomist consultation can help determine the optimal fertilizer type and ratio for your specific conditions.

The fertilizer industry continues to evolve with new technologies:

These innovations are helping farmers maximize the benefits of both compound and mixture fertilizers.

The environmental impact of fertilizers should factor into your decision:

Making environmentally sound choices supports both immediate productivity and long-term sustainability.

A study comparing fertilizer types in maize production found:

This demonstrates how fertilizer choice directly impacts crop performance and profitability.

Research on lettuce cultivation revealed:

These findings highlight the importance of matching fertilizer type to crop requirements and growing conditions.

At the forefront of agricultural innovation, Shandong Lvfeng Fertilizer Co., Ltd. has been pioneering intelligent nutrient solutions since 1999. With ISO 9001 certification and 26+ years of industry experience, Lvfeng specializes in both compound and mixture fertilizers, offering farmers the best of both worlds.

Their extensive product line includes:

With 200,000 tons of annual production capacity across 5 automated production lines, Lvfeng delivers consistent quality that farmers in over 50 countries trust. Their R&D team continuously innovates to address the challenges discussed in this article, developing fertilizers that maximize nutrient use efficiency while minimizing environmental impact.

The key difference between compound and mixture fertilizers lies in their production and composition. Compound fertilizers are created through chemical reactions that bind nutrients into uniform granules, while mixed fertilizers are made by physically blending separate fertilizer materials without chemical bonds.

This fundamental difference affects:

For precision applications where uniform nutrient distribution is critical, compound fertilizers offer clear advantages despite their higher cost. For cost-sensitive operations that benefit from customized blends, mixture fertilizers provide flexibility and value.

The best choice depends on your specific:

By understanding these key differences, you can make informed decisions that optimize your fertilizer investment and maximize your crop yields.

Understanding Key Differences for Better Crop Results

Nutrients chemically bonded together in uniform granules

Physically mixed fertilizer materials retaining separate properties

| Feature | Compound Fertilizer | Mixture Fertilizer |

|---|---|---|

| Production Method | Chemical processing & granulation | Physical bulk blending |

| Granule Composition | Homogeneous (all granules identical) | Heterogeneous (granules vary) |

| Nutrient Distribution | Even, uniform application | Prone to segregation |

| Nutrient Release | Coordinated release timing | Independent component release |

| Customization | Fixed ratios at factory | Highly customizable |

| Cost Efficiency | Higher cost per nutrient | More budget-friendly |

Q: Can I mix my own fertilizer on the farm?

A: Yes, on-farm blending is possible with the right equipment and materials. However, achieving uniform mixes without proper blending equipment can be challenging.

Q: How can I tell if I have a compound or mixture fertilizer?

A: Look at the granules. Compound fertilizers have uniform color and size, while mixtures show visible differences between granules.

Q: Do compound fertilizers always cost more than mixtures?

A: Generally yes, due to the additional processing required, but the price difference varies by formulation and market conditions.

Q: Which type is better for organic farming?

A: Both types can be compatible with organic standards if made from approved materials, though organic farmers often use natural mixture fertilizers.

Q: How do storage conditions affect these fertilizer types?

A: Mixtures are more prone to segregation during storage and may require remixing before use. Compounds generally maintain their integrity better during storage.

For expert formulation advice and high-quality fertilizer products that meet your specific needs, reach out to agricultural supply specialists who can analyze your soil and crop requirements.